Box plants, packaging manufacturers, converters and printers all depend on fast, efficient removal of scrap paper and trim waste to keep production running smoothly. Proper equipment is critical to the success of your recycling and scrap management program. Material type, size, grade, volume and market value all come into play, which can make the equipment selection process complicated.

Commercial and industrial recycling balers reduce the size and volume of materials leading to a reduction in hauls. In most cases, this leads to significant savings in waste. The use of commercial recycling balers allows your company to reduce the amount of labor, time, and energy spent in the recycling process. Our experienced team will help you find a baler that’s right for your needs.

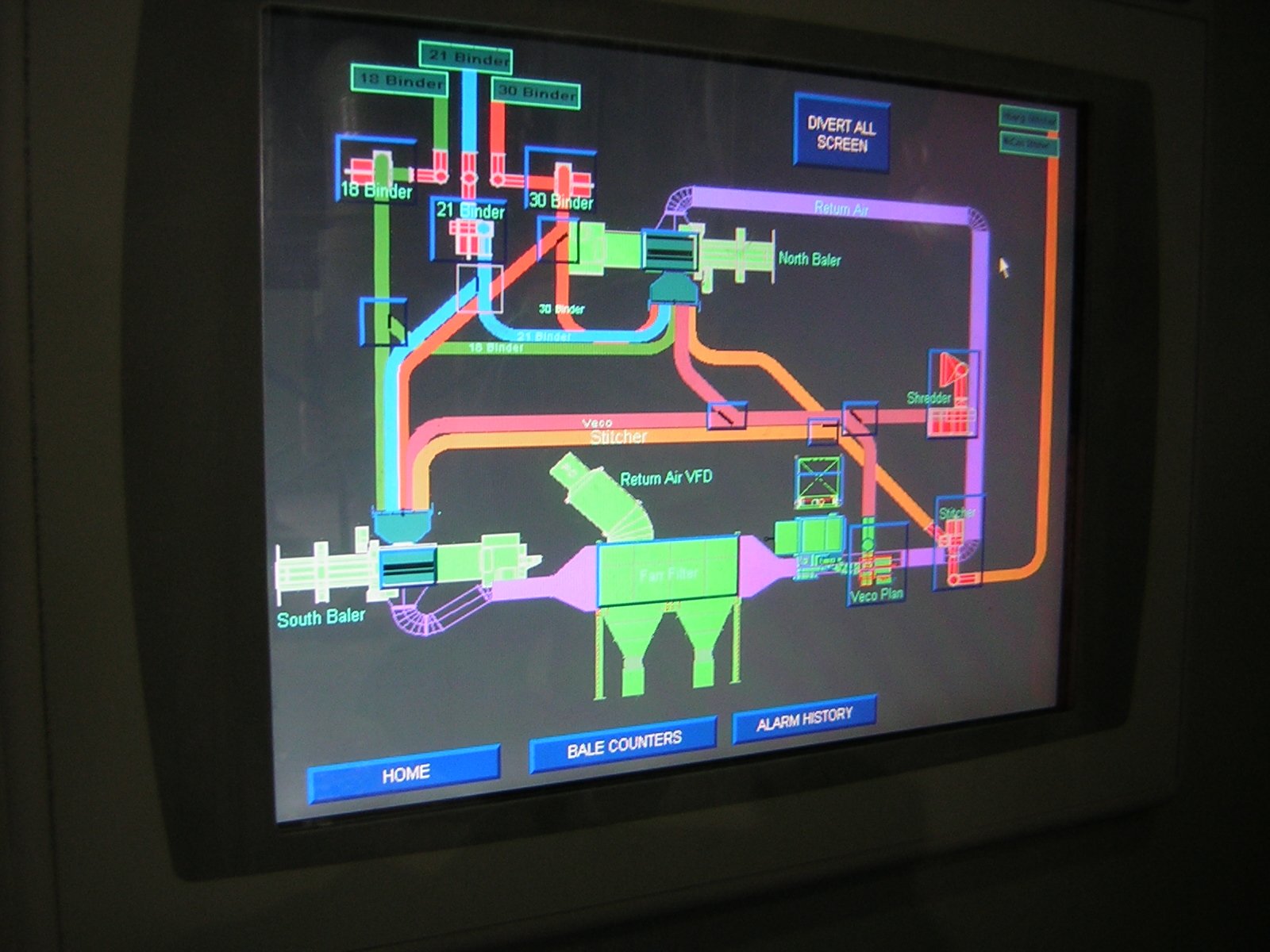

AES has helped hundreds of customers improve their production environment and boost their wastepaper revenues with our automated scrap and trim collection and baling systems. Grade segregation, bale integrity, and weight are significant factors in paper value. We can supply new or reconditioned balers and compactors, shredders, fans, and blowers to meet every need. Let AES show you how to get them most for your recovered fiber.