Rotary grinders, pierce-and-tear style, hammer mills, pulverizers: With so many types of shredders on the market, how do you decide which one is right for your recycling operation? Jeff Dietterich, president of AES, was interviewed for this informative article published in the August edition of Recycling Today magazine. A frequent contributor to recycling and materials management publications, Jeff discusses discusses the primary factors that go into selecting the best shredder for recycling applications.

The Right Tool for the Job

By Deanne Toto, Recycling Today, August 2016

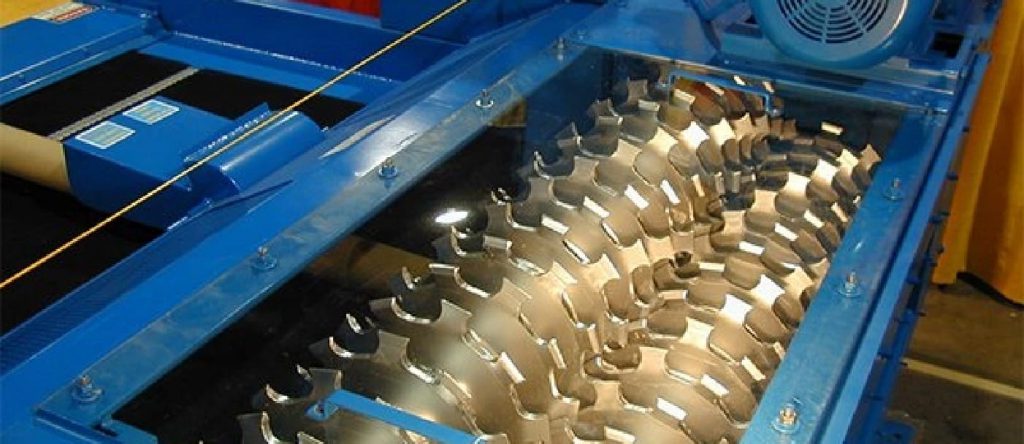

When shopping for shredders, recyclers are confronted by an array of options, from pierce-and-tear styles to hammer mills to strip shredders, to name a few. Some of the available technology is more suited to primary reduction, while others provide controlled sizing.

“The nice thing about available shredding technologies is that there is a solution to recycle almost anything,” says Dave Fleming, sales and marketing director for SSI Shredding Systems Inc., a shredding equipment manufacturer based in Wilsonville, Oregon. “If an item contains materials that have value, there is a shredding solution that could be employed to liberate and prepare that material for recovery.”

Despite the seemingly overwhelming array of options available, a few primary factors can help a recycler narrow down the right shredder style for the application at hand.

Looking for a shredder for your business? Check our our lineup of shredders and shredding equipment.