The AES AirShark™

Ideal for In-House Flexible Packaging Production

Air material separators and industrial fans are the key components of successful pneumatic conveyance systems, providing conveyance power on the front end of the scrap removal process and managing scrap on the back end before baling or compacting. Selecting the right size and type of air material separator is a critical decision that can impact safety, scrap conveyance system performance, and day-to-day operations of in-house packaging production for major retailers.

The experts at AES can help you choose the right components for your pneumatic conveyance system. If you’re producing flexible packaging in-house, you need a robust and versatile material separator with high-volume air handling capacity to manage complex material substrates and films. The AES AirShark™ easily handles these materials without wrapping around rotors or screens for continuous, worry-free operation. Watch the video below to learn more.

Scrap Problems.

Request More Information About the AirShark™ Today.

*Required field

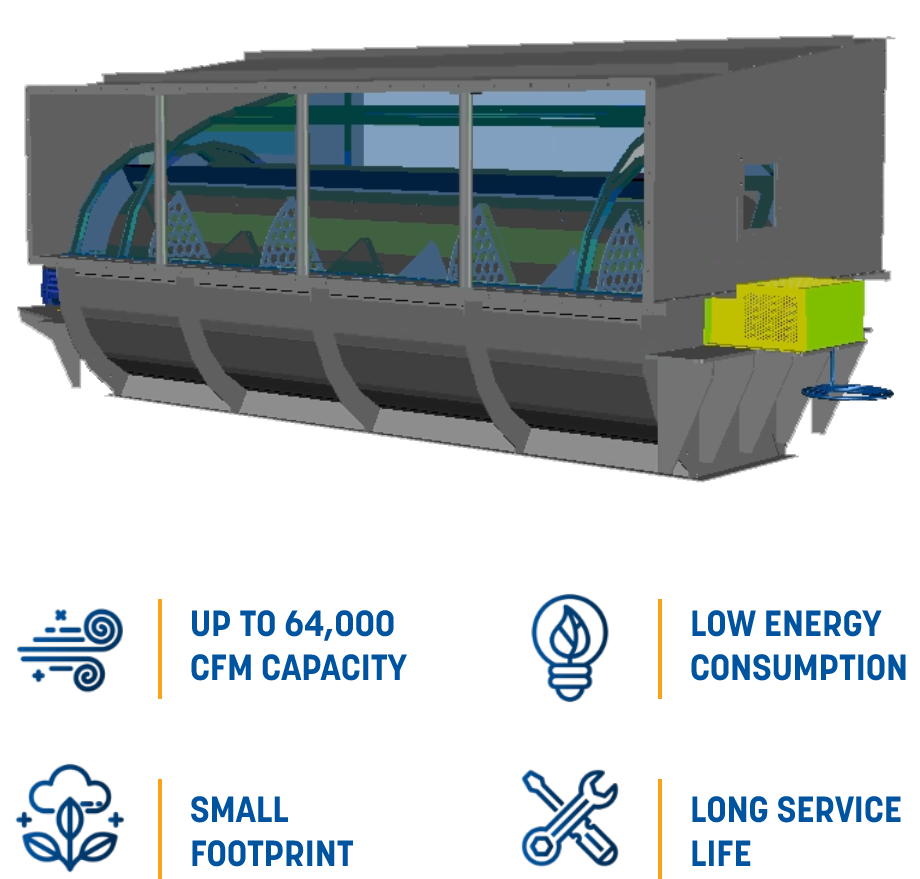

About the AirShark™

The AES AirShark™ is a robust, versatile rotary material separator with a high air handling capacity and a compact footprint for indoor and outdoor applications. An alternative to traditional screen separators and cyclones, the AirShark™ is a simple and effective way to separate material waste and manufacturing byproducts from the airstream without generating any dust.

The flexible-tip sealed rotor allows the user to position the fan upstream or downstream from the separator. The separator eliminates down pressure at the material discharge chute, and the durable, fully sealed V-apex rotor design requires no adjustments for material type.

Contact us to see how an AirShark™ system can replace costly dust collectors and free up space in your facility.

Features and Benefits

- Compact, modular design – installs above or below the roof

- Ideal replacement for cyclones and traditional screen separators

- Durable, heavy-gauge stainless steel screen

- V-apex rotor design for strength and durability

- High air handling capacity up to 64,000 CFM

- Low power consumption for energy savings

- Operates under positive or negative pressure

- No adjusting required for different material types

- Eliminates down pressure at the material discharge chute

- Ideally suited for light film and bag separation and recovery

- Robust, efficient separation, with NO MATERIAL WRAP around rotor

- Installs local to or remote from the manufacturing or baling process

- Can eliminate the need for expensive dust collectors

- Only separator of its kind made in the USA

Uses and Applications

- Flexible Packaging & Film

Scrap removal - Corrugated Box / Folding Carton

Scrap removal, dust control - Material Recycling

Plastic bag capture, light fractions, and film - Manufacturing

Ingredient bag capture and packaging waste

About AES

AES is a leading full-service provider of integrated scrap systems specializing in corrugated scrap, trim, and dust that designs, builds, and maintains economical solutions for more efficient byproduct handling. As a single source for conveyance needs, AES engineers custom scrap systems and works as a partner in process improvement to help businesses achieve greater profitability, productivity, and sustainability in their manufacturing operations.