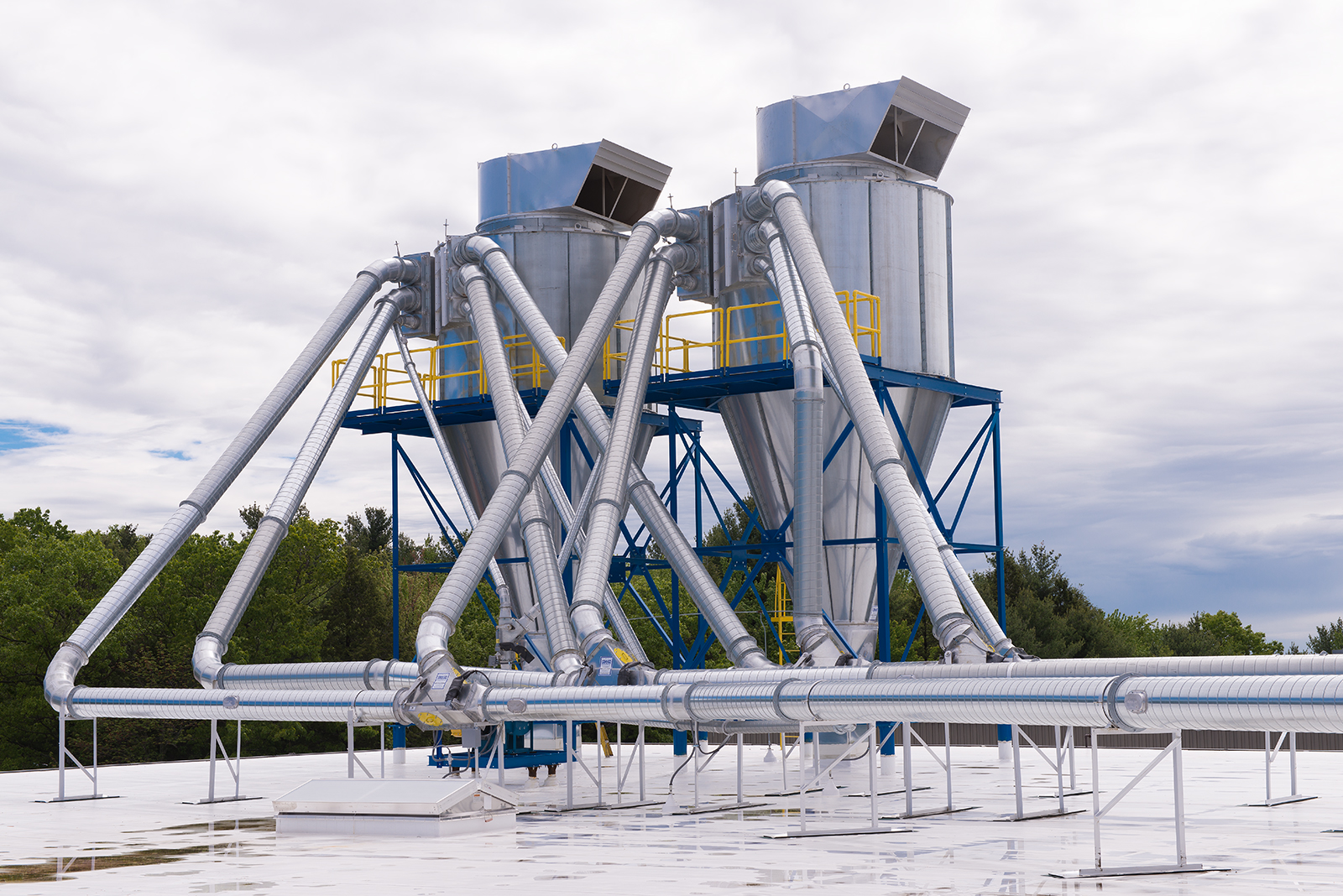

Pneumatic air conveyance systems use high-velocity air to transport materials from process to process within a system. Specialized fans and blowers create the airflow needed to move the materials through enclosed metal ducting, often terminating in an air separator. Additional components such as in-line cutters, shredders, booster fans, intake hoods, and metering conveyors can be used to introduce materials into the air conveyance system. These systems are also used to sort and separate different materials from one another based on relative size or density. This allows for efficient conveyance in the airstream and can reduce or prevent clogs in the ductwork. Pneumatic air conveyance systems are used to convey a variety of manufacturing scrap and byproducts in industries like packaging and paper converting, corrugated box manufacturing, printing and finishing, recycling and solid waste, and others.

Air Conveyance

Systems

We offer a range of turnkey solutions from our own engineering experts meet your unique material conveyance challenges. Whether you need a fully integrated air system for a newly built production facility or an upgrade to an existing system, the experts at AES stand ready to help. We have the tools to collect, convey, separate, shred, condition, and bale many different types of waste and recyclables.

AES designs, builds, and maintains custom air conveyance systems and acts as a partner in process improvement for scrap management and recycling programs, among others. We know that how you handle manufacturing scrap and byproducts impacts what your bottom line looks like. That’s why we offer everything from equipment training for your in-house staff to reliable around-the-clock maintenance.

As a true turnkey partner, we engineer, install, and maintain byproduct handling and conveyance systems that provide lasting value and help boost productivity and profitability. Our systems include all supporting components. Count on AES to provide everything from ducting and divert valves, industrial fans, shredders and granulators, dust collectors, cyclone separators, screen separators, and our exclusive AirSharkTM Rotary Material Separator.