Shredding &

Size Reduction

Shredding can add value to manufacturing operations by preconditioning materials for further processing. AES provides top-quality shredding and size reduction equipment from highly regarded manufacturers. AES has the right shredder or grinder for a wide range of applications and industries, including corrugated box and folding carton, printing and finishing, recycling, security shredding, hard drives and e-waste, product destruction, material preconditioning, and custom and specialty applications. Whether you need a standalone unit or an integrated shredding and baling system, work with AES for all your equipment needs.

Paper Shredders & Other Shredders

Our high-volume shredders include top-feed shredders for continuous material feed. Our security shredders include strip, crosscut, and particle-size shredders. Various shred sizes available to meet any security need, including NSA standards and NAID Certified shredding operations. AES also offer floor sweep shredders to shred bulky wastepaper from production machines prior to sending it through the pneumatic conveyance system. Floor sweeps are also used for quick housekeeping tasks around production equipment, keeping debris from accumulating on the manufacturing floor.

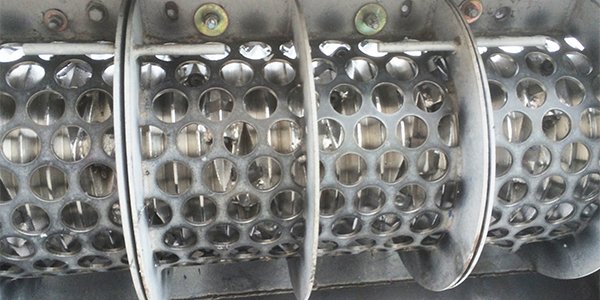

Rotary Grinders

Rotary grinders come in single-shaft or dual shaft and have changeable screens to process a range of materials. These are used for high-security applications like document and product destruction and for size reduction of signature waste, plastics, textiles, and wood.

Hoggers, Hammermills & Cutters

Find hoggers for pre-conditioning large format paper, cores and rolls, and wood waste. We also offer hammermills for heavy duty size reduction needs, such as , wood and pallets, e-waste, rocks, C&D, yard waste, composting and other solid waste applications. Our chopper fans and in-line cutters provide coarse shredding as part of the pneumatic conveyance system.

Granulators

These heavy-duty machines produce very small shred sizes or granules and are often used for reducing plastics to flakes prior to remelt.