Spark Detection/

Fire Suppression Systems

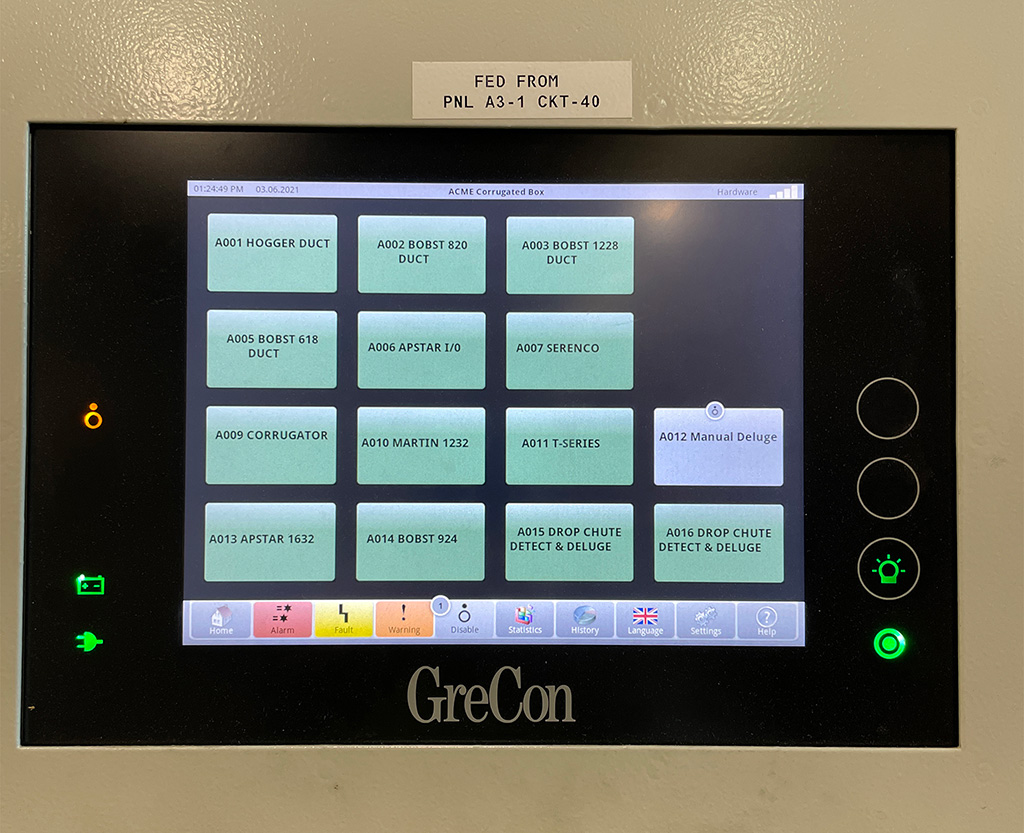

High speed industrial processes produce heat and sparks that can endanger property and lives, even in places you can’t easily see, like ductwork. If a spark is introduced to your facility’s ductwork and travels downstream to a material separator or dust collector, it will contact dust and other combustible materials and can cause a dangerous fire or explosion. Fortunately, there are solutions to manage this risk. Talk to the experts at AES about flame and spark detecting and extinguishing systems. We can recommend and install several types of products that mitigate the risk of fire and explosion in your pneumatic conveyance system. These specialized control systems are a proactive measure to manage risks, keep manufacturing facilities and people safe, and production operations in motion.

When a flame, spark or ember is detected by the system, the extinguishing nozzles deploy a fine mist of water, eliminating the hazard, protecting life and property, and averting a shutdown of production. Flame and spark systems are most often used in combination with other dust control measures to ensure compliance with prevailing NFPA standards. AES provides a full range of flame, spark and explosion control products to keep your pneumatic conveyance system safe and compliant.

Spark Detection/

Fire Suppression Systems Specialized Equipment

Fresh air intake systems are economical to buy and to operate. They are versatile and adaptable, working to reduce heating and cooling bills, eliminate negative pressure problems in plants, and eliminate the need for air exchangers and dust collectors. They also work with die cutters, finishing lines, and shredders and support air quality permits and fire/explosion suppression best practices.

- Flame and Spark Detection

Extinguishing Systems - Explosion Venting

- Flameless Venting

- Chemical Suppression

- Explosion Isolation

- Static Control Systems

- Abort Gates

- Backblast Dampers

- Deluge Systems