Successful production management can be challenging to navigate as a modern manufacturer, particularly as energy costs escalate, environmental concerns among the public rise, and dwindling natural resources add to anxieties in the industry. Plant managers and other executives are always searching for new methods of achieving their productivity and profitability objectives while prioritizing sustainability, but progress really stems from changes made at the system level. Improving the way your business removes and manages byproducts is a great place to start, and implementing an optimized fresh air intake system may be the most impactful adjustment you make. Learn more about fresh air intake systems below.

What Is a Fresh Air Intake System?

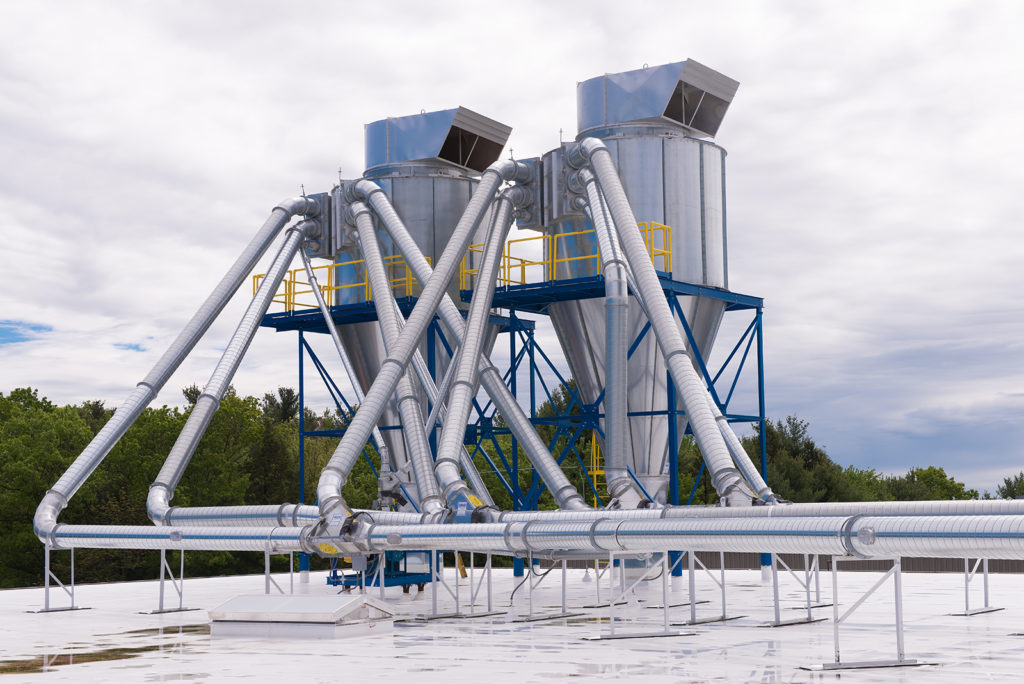

A fresh air intake system is a collection of equipment that operate in a closed loop, using the air outside of a manufacturing plant or production facility to convey scrap and trim along a processing path. They differ from more traditional air filtration systems that exhaust air into the surrounding atmosphere, which can rob plants of conditioned air and create negative pressure problems in buildings that make it difficult for employees to open doors.

Many plant and maintenance managers wonder how to reduce HVAC heat and air conditioning loss in plants and how to reduce energy consumption from production equipment. Installing a fresh air intake system is the answer. They’re often key components of sound production efficiency strategies because not only do they prevent the loss of conditioned air, but they also deliver impressive energy savings, support operational safety efforts, and enhance the long-term performance of air conveyance systems.

Why Implement a Fresh Air Intake System?

Fresh air intake systems provide a host of benefits for manufacturers today. They are versatile and adaptable, easily customized to fit any facility’s existing processes; equipment like die cutters, finishing lines, and shredders can all be integrated into a unique fresh air system. They also remain more cost-effective than traditional air systems to purchase, install, operate, and manage. They can offer substantial year-over-year savings compared to the high equipment, maintenance, and energy costs of cyclones, dust collectors, and energy exchangers. In fact, a fresh air intake system may reduce overall heating and cooling costs and completely eliminate the need for pricier equipment—plus the associated expenses of air quality permits and compliance measures for combustible dust, fire, and explosion suppression systems. Manufacturers can often find additional utility savings and rebates for using fresh air systems through Energy Conservation Measure programs (ECMs).

Along with significant equipment, infrastructure, and operational cost savings come sustainability benefits. Fresh air systems reduce airborne particulates and create healthier indoor air while consuming less energy, which improves the cleanliness, efficiency, and environmental impact of converting equipment. AES’s fresh air intake solutions are also fully compliant with prevailing air quality regulations and standards. With this innovative approach to energy management, companies can confidently fulfill the commitments they make to adopting more sustainable practices and manufacturing more environmentally conscious products.

The Benefits of a Fresh Air Intake System

- Prevent the loss of conditioned air

- Improve the quality of air in facilities

- Create more balanced air environments

- Avoid the need for added equipment

- Lower energy consumption levels

- Reduce heating and cooling costs

- Achieve economical air conveyance

- Support long-term sustainability goals

Learn More About Fresh Air Systems

Installing a fresh air intake system can be a simple, stress-free project to augment your scrap management program. If you partner with an experienced provider like AES, you can implement a custom solution that easily meets your safety, compliance, and productivity needs without causing major disruptions to facility operations.

Read a free case study to see how one packaging provider improved the efficiency of its manufacturing processes and eliminated the need for expensive filtration equipment with an expertly designed and installed fresh air intake system from AES.

Talk to the experts at AES to inquire about fresh air intake systems for your business.

Download Our Fresh Air Systems Case Study